EV BATTERY AI SOLUTIONS

AI-Powered EV Battery Layer Inspection System

Our advanced AI system specializes in precision X-ray analysis of lithium-ion battery layers, providing automated quality control with accuracy down to 0.01mm. Through real-time inspection, the system ensures battery safety and performance by:

- Measuring multiple layer overhangs with sub-millimeter precision

- Validating measurements against industry standards (0.2mm - 1.3mm)

- Providing instant pass/fail verification with detailed measurements

- Delivering clear visualization of internal structure through high-resolution X-ray imaging

- Generating automated measurement reports with precise numerical readings

This intelligent quality control solution streamlines manufacturing by combining advanced AI technology with precise X-ray imaging, ensuring each battery meets strict safety and quality standards through consistent, accurate inspection.

Join us in transforming businesses through AI. Together, we'll turn technological possibilities into practical solutions that deliver real results.

Check the results below...

Precision X-Ray Layer Analysis for EV Batteries

AI-Driven Quality Control with 0.01mm Measurement Accuracy

- A high-contrast grayscale X-ray image showing multiple parallel battery layers, with distinct edges visible in light and dark tones. The left portion shows the raw X-ray image, while the right side displays the same image with AI measurement annotations

- The image contains overlaid measurement data in cyan text, showing precise measurements for each layer's overhang, with numbering from Layer 1 through Layer 7 and their corresponding measurements between 0.27mm and 0.35mm

- Blue line at the bottom of the image marks the reference edge, while orange markers on the right indicate where the AI system is taking measurements for each layer's overhang

- The text "OK" in orange at the top right indicates that all measurements fall within the acceptable range of [0.2mm - 1.3mm], confirming the battery assembly meets quality standards

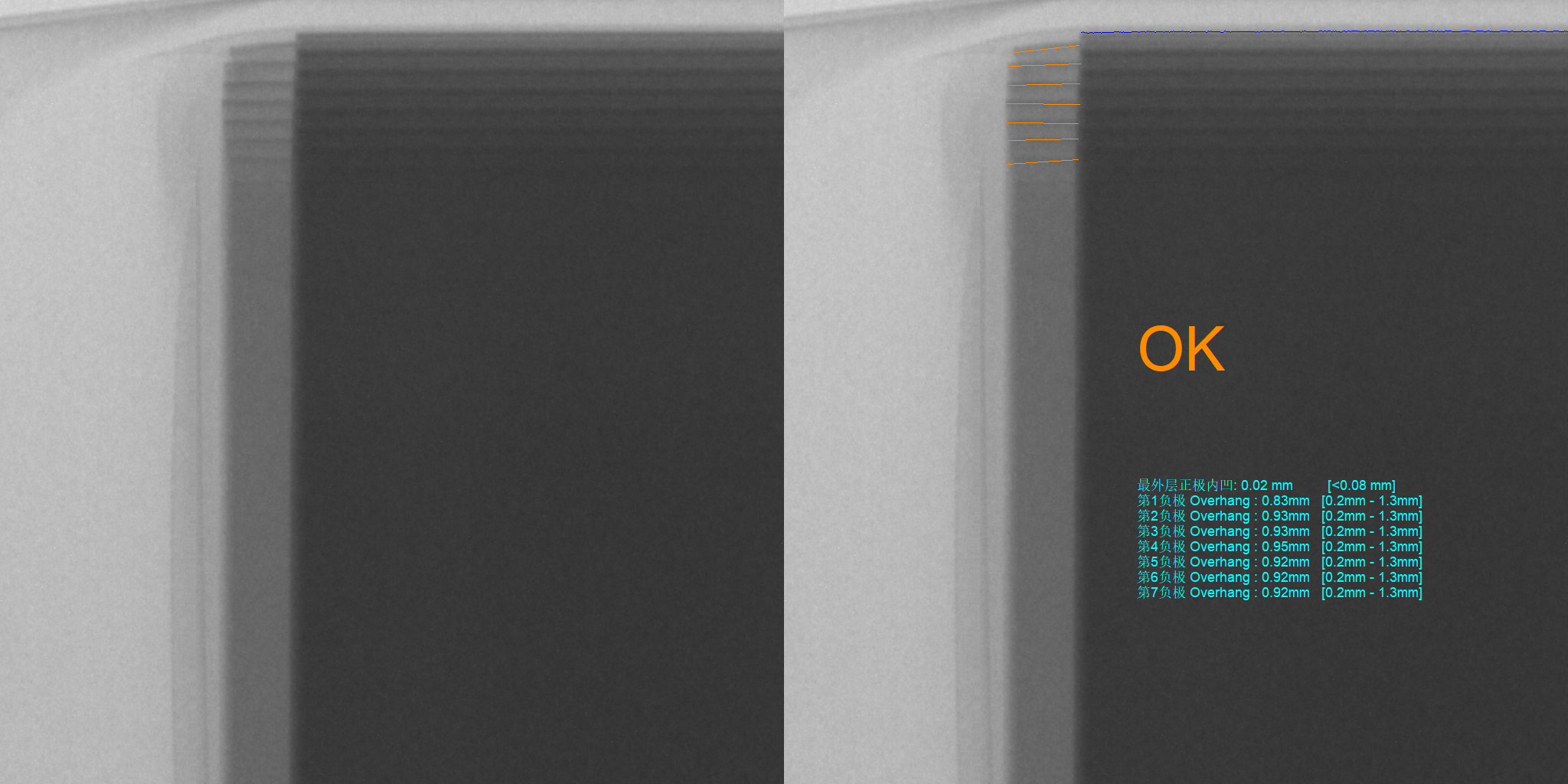

Automated Layer Overhang Inspection

High-Precision X-Ray Analysis with 0.02mm Accuracy and Real-Time Validation

- A high-resolution X-ray image of battery layers with a side-by-side comparison - raw X-ray on the left and AI-analyzed version with measurements on the right

- The AI system is measuring overhang distances for seven layers (Layer 1 to Layer 7), with values ranging from 0.83mm to 0.95mm, at a precision level of 0.02mm

- Orange markers on the right side indicate the exact measurement points for each layer, with all measurements falling within the acceptable range of [0.2mm - 1.3mm], while the blue reference line ensures consistent and accurate measurement points from the base

- The "OK" status in orange confirms that all measurements meet quality control specifications, demonstrating the system's ability to validate layer alignment with high precision

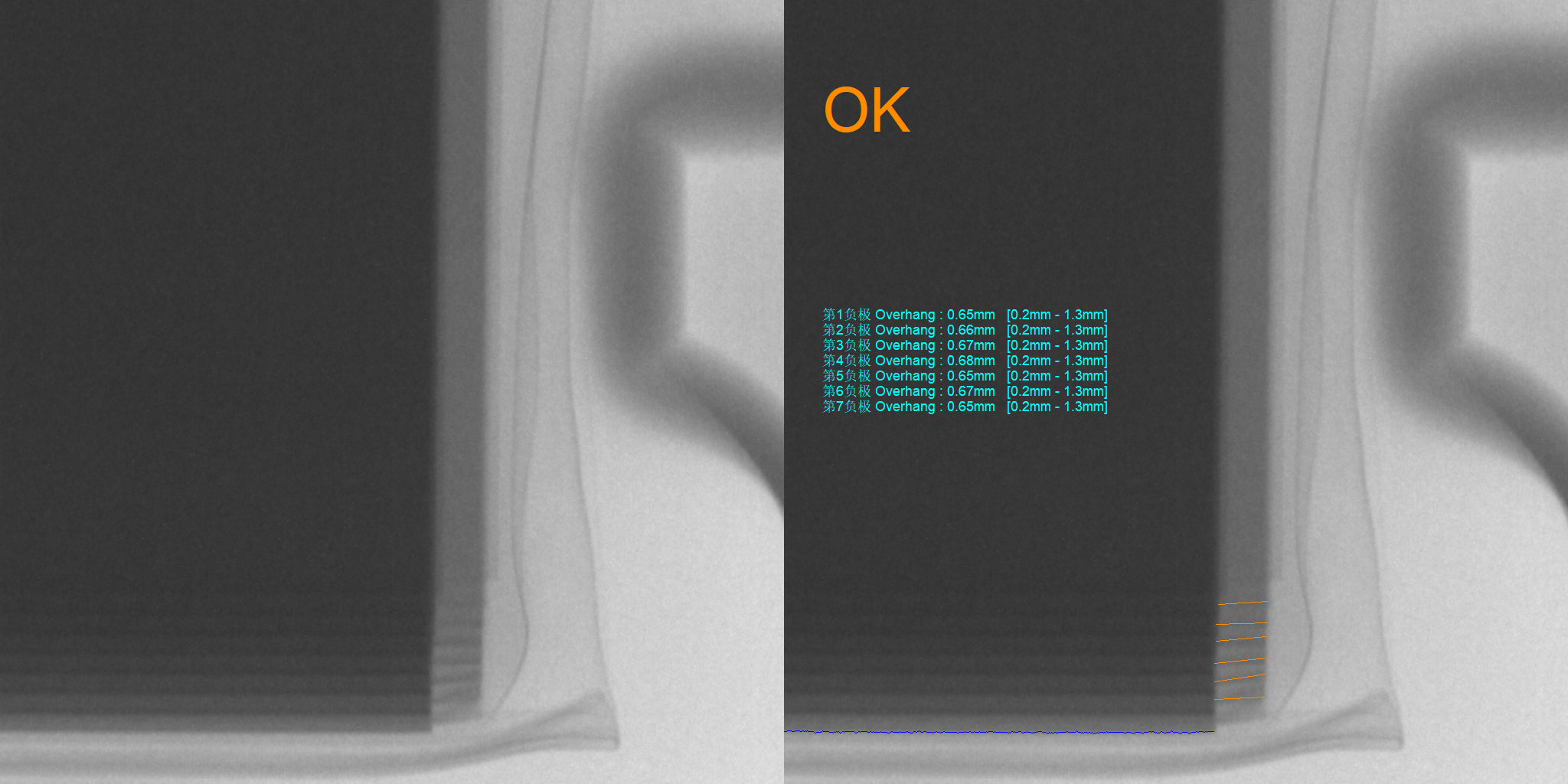

Multi-Layer Uniformity Validation

AI-Powered X-Ray Analysis with Layer Consistency Control (0.65-0.68mm Range)

- The high-resolution X-ray image shows split-screen analysis with raw image on left and AI-analyzed measurements on right, demonstrating consistent layer measurement capabilities

- The AI system is measuring seven layer overhangs (Layer 1 to Layer 7) with values ranging from 0.65mm to 0.68mm, showing excellent uniformity across layers within the acceptable range of [0.2mm - 1.3mm]

- Orange markers on the right side indicate measurement points for each layer, with the blue baseline reference line at the bottom ensuring accurate and consistent measurement positioning

- The "OK" status in orange confirms quality standards are met, validating the measurement consistency across all layers

Dynamic Layer Transition Analysis

AI-Enhanced X-Ray Inspection with 0.03mm Precision for Variable Overhang Validation (1.25-0.65mm)

- Split-screen analysis displays raw X-ray image (left) and AI measurement overlay (right), with a precision level of 0.03mm for layer examination

- The AI system measures gradual variations in layer overhangs from 1.25mm at the top (Layer 1) to 0.65mm at the bottom (Layer 7), demonstrating its ability to detect and validate intentional layer transitions

- Orange markers and the blue baseline reference work together to ensure precise measurement points, while all measurements remain within the acceptable range of [0.2mm - 1.3mm]

- The "OK" status confirms that this gradual transition in layer overhangs meets design specifications, showcasing the system's capability to validate complex layer arrangements

Progressive Layer Expansion Analysis

AI-Powered Inspection System with 0.02mm Precision for Ascending Overhangs (1.07-1.40mm)

- Split-screen comparison shows raw X-ray image (left) and AI-analyzed view (right), achieving 0.02mm measurement precision for detailed layer inspection

- The AI system analyzes seven layers (Layer 1 to Layer 7) with increasing overhang measurements from 1.07mm to 1.40mm, all within the acceptable range of [0.2mm - 1.3mm]

- Orange markers indicate precise measurement points for each layer, with the blue baseline reference line ensuring accurate measurement positioning

- The "OK" status validates that these progressive layer measurements meet quality specifications, demonstrating inverse transition pattern compared to the previous image